Thermal Imagery – From the Military to Your Business

New technologies seem to be developed at a borderline alarming pace but many of them remain out of reach of anyone but the governments and militaries of the world until popular applications are found and mass production begins. Thermal imaging is one such example.

Developed for military use as early as 1958 in order to be able to see targets in the darkness or across the smoke of a battlefield. The first commercially available thermal camera was developed for powerline inspections in 1965 and remained in limited usage until 1997. This is when FLIR (the company that had developed the original technology under the name of AGA) brought out the first thermal cameras that didn’t require a liquid coolant (originally the sensor required cooling via liquid nitrogen, not a practical solution for the ‘home user’).

This new iteration of the technology had no moving parts, making it easier to mass produce and so lowering the price and finally putting the technology within the reach of the business professional.

Industry was relatively quick to tap into the potential of the thermal image to provide information about electrical equipment and power lines and new uses are being established as time passes. The thermal image is proving to be a powerful tool especially when combined with the agility of the drone and its ability to reach inaccessible areas to provide a bird’s eye view.

Drone Media Imaging is equipped with state of the art drones and thermal imaging cameras as well as a licensed and experienced team to delivery a service to meet your imaging needs. Find out more about our thermal imaging service here.

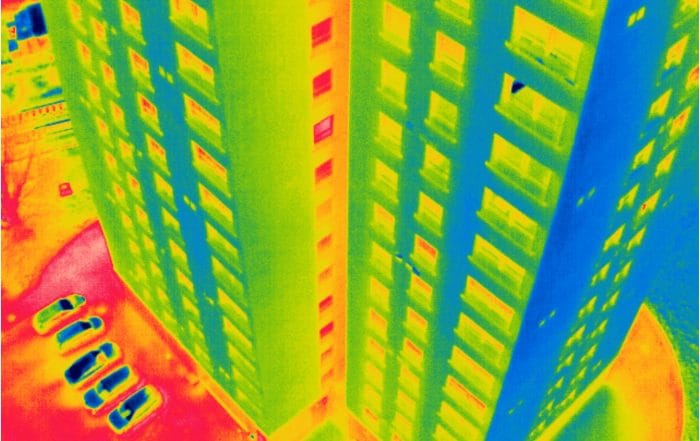

Level 3 Thermography Reporting Project – 3 Multi-Storey Residential Blocks

We supported a large thermal inspection project across three residential buildings by providing certified Level 3 thermographic reporting based on drone data collected by the client. Using a protocol we developed, they captured radiometric thermal images, which we analysed remotely to identify heat loss, glazing issues, and roof moisture indicators. This collaborative approach showcases how our clients can carry out surveys independently, while we deliver professional-grade thermographic interpretation and reporting — cost-effectively and without needing site access.

The Importance of Solar Panel Inspections in Spring

Spring and summer are peak months for solar energy production—ensure your panels are operating efficiently with a professional thermal imaging inspection. Compliance with IEC62446-3:2017 is essential for both commercial and domestic systems, helping to prevent faults, optimise performance, and maintain insurance coverage. Book your inspection today!

Facebook, Instagram and Threads Removal

Departing Facebook, Twitter, and Instagram to Uphold Ethical Principles In an era increasingly shaped by the influence of powerful social media platforms, Drone Media Imaging has made the principled decision to leave Facebook, [...]

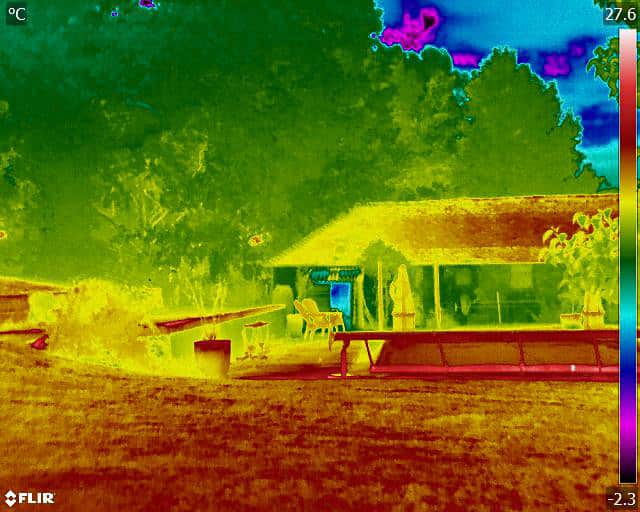

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.