The Crucial Role of Diodes in Solar Panels

Enhancing Energy Conversion and Preventing Damage: The Importance of Diodes in Solar Panels

Solar panels are becoming an increasingly popular choice for generating clean and renewable energy. However, to ensure optimal energy conversion and efficient performance, it is crucial to understand the role of diodes in solar panels and the importance of detecting faults through thermal imaging. Diodes are semiconductor devices that allow the flow of current in one direction while blocking it in the opposite direction.

In solar panels, diodes are essential for several reasons. Primarily, they prevent reverse current flow, ensuring that the energy generated by the solar cells is not wasted or lost. Without diodes, shaded or defective cells could draw current from the remaining functional cells, causing a significant drop in overall panel efficiency.

The Role of Diodes in Solar Panels: Ensuring Optimal Energy Conversion

Diodes are essential components in solar panels that play a critical role in ensuring optimal energy conversion. Solar panels are made up of numerous photovoltaic (PV) cells that convert sunlight into electricity. These PV cells generate direct current (DC), which needs to be converted into alternating current (AC) for household or commercial use. Diodes act as one-way valves, allowing the flow of current in a single direction, preventing the reverse flow of electricity. This ensures that the DC current generated by the PV cells is efficiently directed towards the inverter for conversion into AC power.

Diodes are essential components in solar panels that play a critical role in ensuring optimal energy conversion. Solar panels are made up of numerous photovoltaic (PV) cells that convert sunlight into electricity. These PV cells generate direct current (DC), which needs to be converted into alternating current (AC) for household or commercial use. Diodes act as one-way valves, allowing the flow of current in a single direction, preventing the reverse flow of electricity. This ensures that the DC current generated by the PV cells is efficiently directed towards the inverter for conversion into AC power.

Moreover, diodes also protect the solar panels from potential damage, electrical surges or fluctuations caused by shading or partial module failure. When a PV cell is shaded or malfunctions, it can significantly reduce the overall energy output of the panel. Diodes prevent this by isolating the affected cell, allowing the rest of the cells to continue functioning optimally, by acting as a safety valve, and redirecting excess current away from the panel, safeguarding it from overheating or potential fires. By effectively managing the flow of current, diodes help maintain the overall performance and longevity of solar panels. This feature is particularly important in large-scale solar installations, where panels are interconnected in series.

Detecting Faults with Thermal Imaging: A Crucial Step in Solar Panel Maintenance

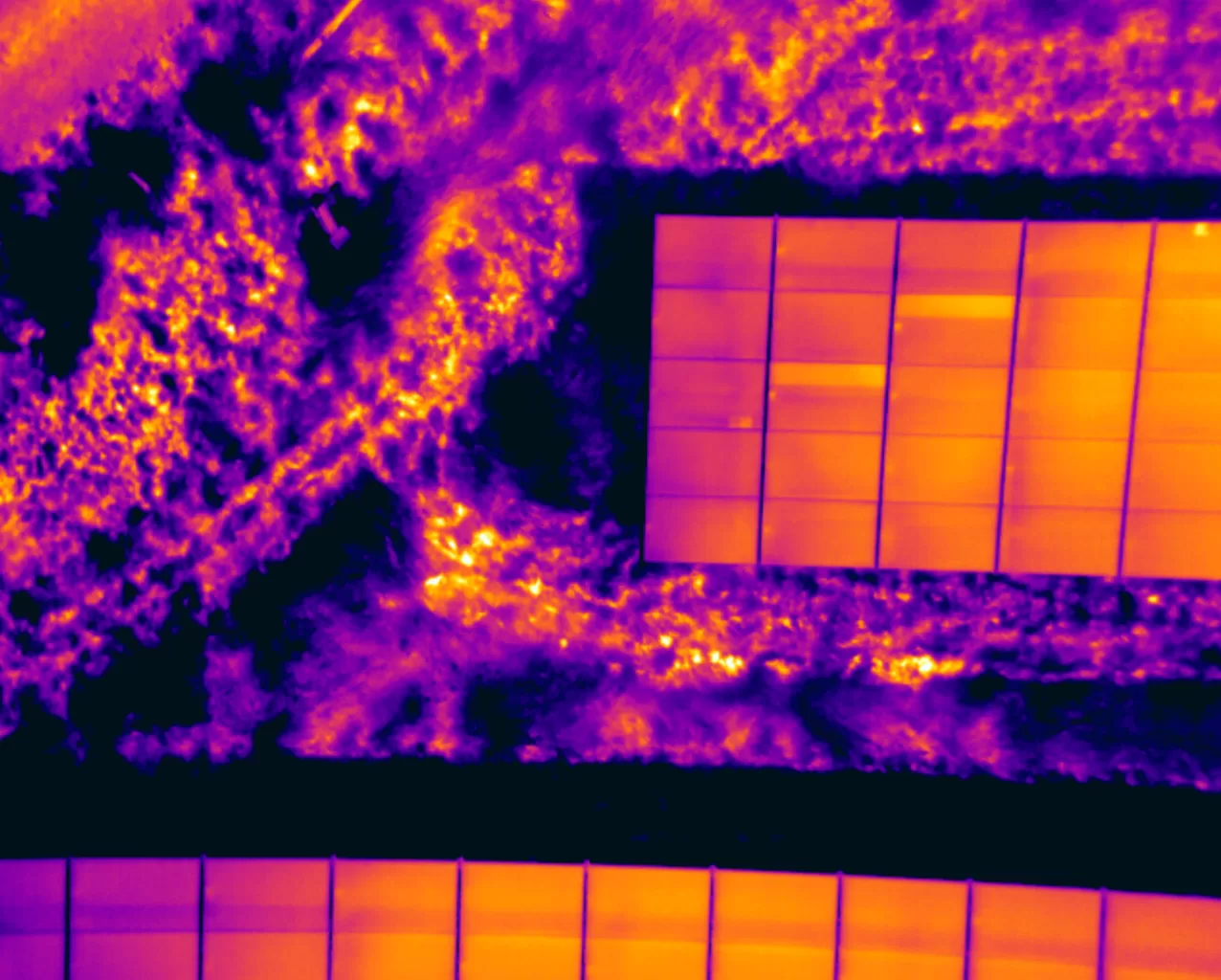

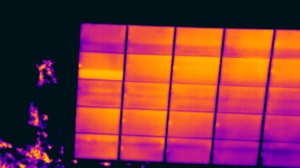

Thermal imaging is an invaluable tool in detecting faults and identifying potential issues in solar panels. By using infrared technology, thermal imaging cameras attached to UAV drones can capture the heat signatures of various components in the solar panel system. This allows thermographers and technicians to identify ‘hotspots’, which can indicate faulty or malfunctioning diodes, loose connections, or damaged cells.

Detecting faults early on is crucial to prevent further damage and ensure the optimal performance of solar panels. Faulty diodes, for example, can cause a phenomenon known as “hot-spotting,” where excessive heat is generated in a specific area of the panel. This not only reduces energy output but can also lead to irreversible damage to the solar cells. By using thermal imaging, thermographers can quickly identify these hotspots and take necessary actions to rectify the issue, thus preventing potential system failures and maximising the overall efficiency of the solar panel system.

Drone thermal inspections offer several advantages over traditional methods. They reduce the time and cost associated with manual inspections, as large solar installations can be surveyed more efficiently. Additionally, drones can access hard-to-reach areas, such as rooftops or elevated arrays, without the need for scaffolding or ladders. This enhances safety for technicians and minimises potential damage to the panels during inspection.

Implementing IEC Solar PV Surveys for detecting diode faults , to ensure the accuracy and reliability of thermal imaging data, it is essential to follow industry standards such as those set by the International Electrotechnical Commission (IEC). IEC solar PV inspections provide guidelines for conducting thorough and standardised inspections, including the detection of diode faults. By adhering to IEC standards, technicians can ensure that thermal imaging inspections are conducted using calibrated equipment and professional procedures. This helps to minimise false positives and negatives, ensuring accurate fault detection and reducing the risk of unnecessary maintenance or repair costs.

Importance of Diodes and Thermal Imaging for Efficient Solar Panel Performance

The combination of diodes and thermal imaging is vital for maintaining efficient solar panel performance. Diodes ensure that the energy generated by the PV cells is directed towards the inverter without any loss or reverse flow. This not only maximises energy conversion but also protects the panel from potential damage due to shading or partial module failure.

Diodes play a crucial role in solar panels by ensuring optimal energy conversion and protecting the system from potential damage, diodes ensure optimal panel performance and longevity. The use of thermal imaging as a maintenance tool further enhances the efficiency of solar panels by detecting faults and addressing issues before they become major problems. By understanding the importance of diodes and thermal imaging in solar panel systems, we can ensure the long-term performance and sustainability of renewable energy generation.

IEC Solar Inspection Services

We are certified thermographers, experienced in solar panel inspection to IEC standards. We can complete both the structured and compliant data capture through to the formal inspection report.

As approved drone pilots we work throughout the UK to provide both aerial and ground based thermography services. Fully insured and certified by the CAA with enhanced permissions for day and night time flights

Drone Services Enquiry

Thermography|Inspections|Solar|Photogrammetry|Filming|Photography

Discover how drone technology can enhance your operations with a free quotation from our experts. Get a Free Quote or Make an Enquiry Today!

related posts

PID (Potential Induced Degradation) is a common phenomenon that affects the performance and lifespan of solar panels. It occurs when the voltage potential between the solar cells and the frame of the panel creates a current flow, causing the cells to degrade over time. Understanding PID and taking steps to prevent it is critical for maximizing the efficiency and longevity of your solar panels.

BBC's coverage of the Vaisakhi Nagar Kirtan in Nottingham shed light on Sikhism, with Drone Media Imaging shooting aerial general views, capturing the vibrant traditions and beliefs. Viewers praised the inclusive coverage, fostering understanding and respect among communities. The Sikh Motorcycle Club UK exemplifies unity, embracing faith and culture, inspiring others to do the same.