Drone Thermal Imaging and Property Inspection

When is the best time to use a Thermal Infrared camera for conducting roof inspections?

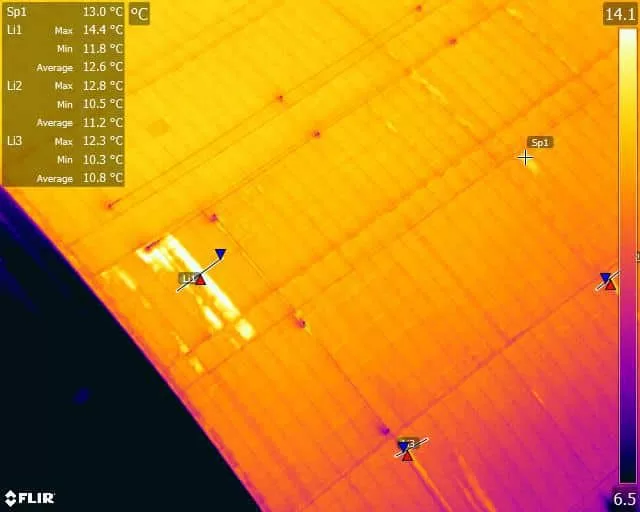

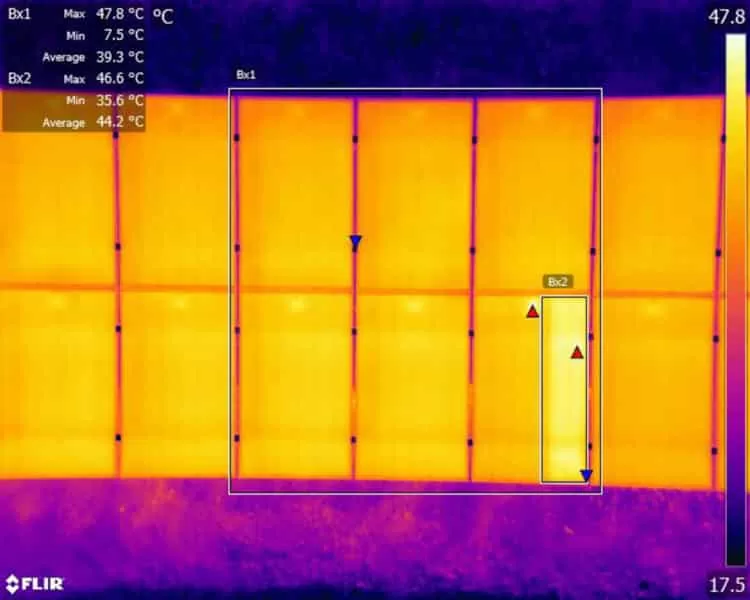

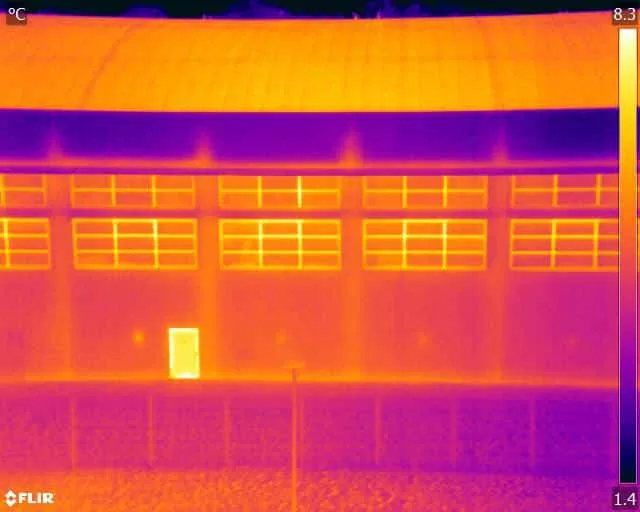

UAVs or Drone’s as they are known have the ability to create great aerial photography and videography which has been understood for some times, however, were you aware that they can also be fitted with thermal infrared cameras to add a whole new dimension to property inspections? Thermal imaging cameras provide a non-contact temperature measurement across areas that are hard to access or see from a ground.

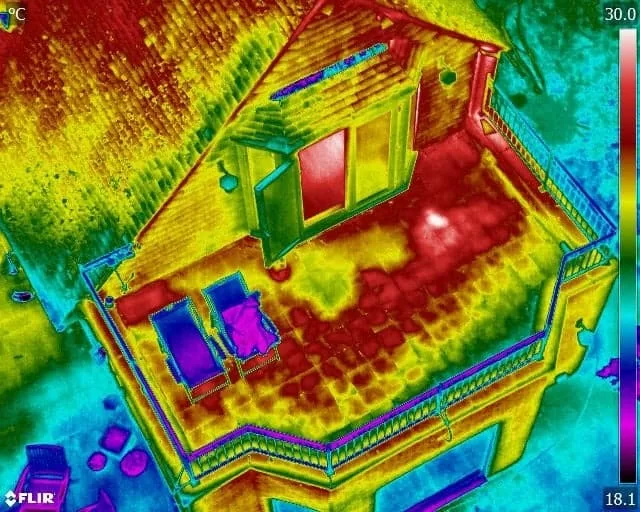

The health and safety risks associated with working at height are minimised when using drone technology, as are the risks of causing damage to the structure through the inspection process itself. With UAVs carrying thermal imaging cameras, temperature data is captured in real-time as well as recorded both quickly and accurately with the resulting heat map presented as colour images in both a qualitative and quantitative reporting format. Image analysis and reporting completed by a thermographer appropriately trained and certified, can identify potential fault areas that would have remained hidden to the human eye until serious damage had occurred.

Key Areas to Use a Thermal Drone

In all cases thermal imaging solutions when deployed from a UAV drone, offers a non-destructive, simple, and cost effectively solution to getting infrared analysis from hard to reach and difficult to see places.

Drone Media Imaging use the latest thermal infrared equipment and fully trained and insured thermographers, get in touch to discuss your thermal survey and inspection and we will provide you with a clear no obligation quotation.

Thermal Survey and Inspections

Drone media imaging are qualified, approved and insured aerial thermographers

specialising in providing thermal imaging and anlysis reporting through the use of Drone technology

Drone Services Enquiry

Thermography | Inspections | Solar | Photogrammetry

Discover how drone technology can enhance your operations with a free quotation from our experts. Get a Free Quote or Make an Enquiry Today!

related posts

Thermal imaging technology is a powerful tool for building surveys, allowing for the detection of hidden issues that affect a building's efficiency and structural integrity. It can uncover insulation deficiencies, diagnose HVAC system malfunctions, and even detect water leaks and electrical faults. By utilizing thermal imaging, property owners and surveyors can proactively address problems, saving time, money, and preventing further damage. As we move towards smart building diagnostics, thermal imaging is a critical component in ensuring the longevity and sustainability of our built environment.

Drone Media Imaging invests in new cuttin-edge photobrapmmetry survey and inspection equipment with the new DJI M300RTK and P1 Suvery Grade Camera