Drone Inspections and How UAVs Can Help

There is almost no end to the areas of commerce and industry where visual inspections of one kind or another play an important role.

Where these inspections take place at height or in other inaccessible areas, drones can provide a practical and cost-effective alternative to using the actual eyes of the inspector. Where a UAV is deployed, the images and /or footage replace the inspector’s vision allowing them to examine and re-examine conditions from the comfort of their desk. In certain circumstances, video can be reviewed in real-time by an inspector at a remote location while the drone is in operation, but most times, detailed imagery can be captured by the pilot for later sharing and review.

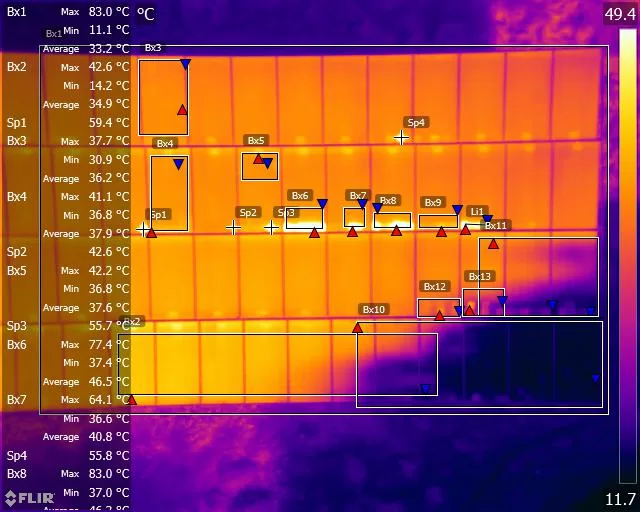

The information captured does not necessarily need to be limited to what is visible. The addition of a thermal imaging sensor can capture information that would remain invisible to the naked eye, allowing advanced diagnostics to take place. Assessment of insulation continuity, water ingress, thermal bridging, and heat loss are all areas where thermal imaging can provide real insight into building health in a non-destructive way and safe way.

Sending a drone piloted by certified ground-based personnel has an obvious advantage when it comes to safety. Sending inspection personnel into high or otherwise inaccessible areas can come with health and safety concerns and sometimes also with a significant price tag. Drone inspections avoid the need for this in terms of if initial assessments, ensuring personnel is only deployed if remedial action is identified, and then to the precise areas where they are needed and armed with plenty of information about what they will find when they get there.

This can mean initial and obvious savings when compared with the costs associated with scaffolding and elevated platforms and in the cost of deploying skilled repair personnel when there may not even be a fault to fix. This lower cost and ease of inspection can mean that they can be scheduled more frequently – prevention rather than cure being the ultimate goal.

Each inspection is recorded for posterity which means a detailed schedule of condition is automatically created. Records can then be retrieved and reviewed to examine progress over time.

Where Can Drone Inspections be Useful?

Drones can offer significant advantages over traditional inspection methods in so many areas. Get in touch to find out how Drone Media Imaging can help you to achieve your business goals whilst reducing costs.

Get your Commercial Property Photographed today!

We are certified and approved drone pilots and work throughout the UK to provide both aerial and ground-based property photography

Drone Services Enquiry

Thermography | Inspections | Solar | Photogrammetry

Discover how drone technology can enhance your operations with a free quotation from our experts. Get a Free Quote or Make an Enquiry Today!

related posts

How To Detect A Faulty Solar Panel.? When faults develop with a solar panel the result is that these cells will heat up. This is because the energy generated by the electrons moving around is not flowing through the panel and onto the convertor, and must manifest somehow, it doesn’t can’t just disappear, so the energy becomes heat.

Drone Media Imaging invests in new cuttin-edge photobrapmmetry survey and inspection equipment with the new DJI M300RTK and P1 Suvery Grade Camera