Photogrammetry For Roof inspections, Solar Panels, and Hard-To-Reach Assets: A Technical Approach

Photogrammetry for roofs, solar panels, and complex vertical structures requires far more precision than standard terrain mapping. This post from explores why traditional workflows fall short and how operators can use tools such as terrain-following, custom camera profiles, circlegrammetry, and automated vertical scanning to achieve consistent results. Packed with real-world examples and scientific validation, it provides a practical technical guide to improving model accuracy, mission repeatability, and inspection efficiency across challenging commercial environments.

Capturing quality photogrammetry data from vertical and elevated structures remains one of the trickier challenges in commercial drone operations. Traditional surveying workflows fail here. Kristaps Brass, Product Owner at UgCS, has spent years working with operators who tackle these missions daily. Solar farms, building facades, communication towers, dam inspections. The pattern is consistent: manual flying burns time and money, and processed models show gaps where critical details should be. This article covers what actually works, based on field-tested methods and real operator feedback.

TL;DR – Key Takeaways

A quick summary of the essential insights from this UgCS technical article.

- Standard grid mapping fails on vertical or angled assets such as roofs, facades, and solar arrays.

- Advanced flight planning is essential to maintain correct geometry, heading, overlap, and GSD.

- Circlegrammetry improves 3D reconstruction and reduces image count while increasing accuracy.

- Vertical scanning provides consistent standoff distance and reliable detail for large structures.

- Terrain-following and mission templates support repeatable, safe, and efficient operations.

- Correct camera profiles ensure thermal and RGB datasets align without coverage gaps.

In short, accurate inspection data depends on disciplined planning, correct flight geometry, and tools designed for complex structures.

Why Standard Photogrammetry Fails on Vertical Assets

Most photogrammetry software optimises for one thing: horizontal terrain mapping. The camera points straight down at 90 degrees (nadir), capturing overlapping images as the aircraft moves in a lawn-mower pattern across flat or gently rolling ground.

This breaks immediately when you point it at a solar array or building wall.

The solar panel problem: Panels are installed at angles between 15 and 40 degrees, depending on latitude and mounting system. Camera configuration varies by operator workflow. Some fly nadir (straight down), others set the camera perpendicular to the panel angle. Both approaches can work, but the flight geometry must support the camera orientation.

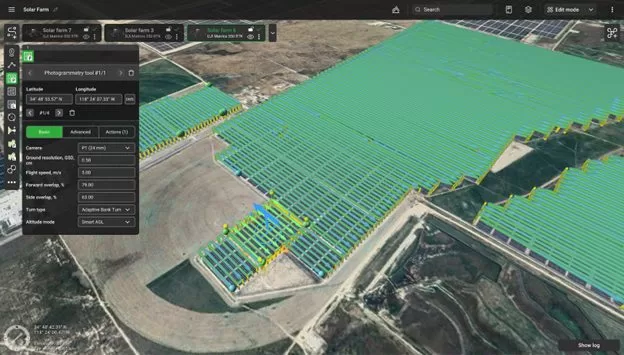

The critical requirement is constant drone heading. For solar panel inspections, the drone needs to face the panels, not the direction of movement. Most basic flight planners can’t separate heading from flight direction. This is where a professional mission planning tool like UgCS becomes essential. Without the ability to decouple the drone’s heading from its flight path, your drone ends up constantly rotating to face forward along the flight path, which creates gimbal compensation issues and inconsistent imagery.

Overlap calculations present another problem. Solar thermal work requires dual sensors: thermal for defect detection, RGB for reference. Thermal cameras have significantly narrower fields of view than wide RGB cameras. If your flight planner calculates overlap based on the RGB camera, your thermal coverage will have gaps. You need software that can base spacing and trigger intervals on the thermal sensor’s actual FOV.

Flight planning tools need flexibility to adapt to different operator requirements. Solar panel inspections aren’t standardised. Panel angles vary. Sensor combinations vary. Workflows vary. If your software forces you into a one-size-fits-all approach, you’re fighting the tool instead of solving the problem.

The vertical structure problem: Building facades, towers, and dam walls require near-perpendicular camera angles to the vertical surface. Horizontal double-grid flights help with building a 3D model, but lack details that can only be captured with vertical inspections. Processing software struggles to reconstruct surfaces when most images show the same face from similar angles. You end up with incomplete meshes and texture warping exactly where you need precision. For vertical inspections, automation is key because it ensures consistent and sufficient image overlap without gaps.

What Good Data Actually Requires

Ground Sampling Distance (GSD) consistency matters more than most operators realise. If your GSD varies by 50% across a structure, your crack detection threshold just becomes unreliable. On vertical surfaces, maintaining a constant distance is harder than on flat terrain because you’re fighting both altitude changes and standoff distance simultaneously.

A recent scientific study by MeteoSwiss demonstrated this principle with unusual clarity. Researchers needed to measure thousands of hailstones with millimeter accuracy before they melted. At 1mm/px resolution, a 10mm hailstone spans 10 pixels with clean edge detection. At 1.5mm/px, the same object shrinks to 6.7 pixels, and small features disappear into noise.

The team achieved 98% detection accuracy in controlled experiments by maintaining exactly 8 meters AGL across uneven meadow terrain using automated terrain-following. When they surveyed a real hailstorm event at 12 meters AGL (yielding 1.5mm/px), detection accuracy dropped to 81%. That 4-meter difference mattered.

Scale that concept to roof inspections, where you’re looking for 2-3cm cracks or solar panels where you need to identify 5cm hotspots. Your altitude control directly determines whether you can detect what you’re being paid to find.

Angular coverage determines reconstruction quality. Standard grid flights capture one viewing angle per location. Circlegrammetry (orbital photogrammetry with an inward-facing camera) captures the same point from multiple angles in a single pass, producing cleaner 3D geometry with fewer total images.

Camera trigger timing and heading control become critical on complex flight paths. If your heading drifts while orbiting a tower, your gimbal has to compensate mid-flight, introducing motion blur. Precise waypoint generation with controlled heading transitions solves this.

Circlegrammetry: Orbital Capture for Complex Geometry

Circlegrammetry utilises many circular orbits to survey an asset, with the camera pointing inward at angles of 45 to 70 degrees. This approach allows for capturing significantly more accurate geometry compared to traditional methods, sometimes even with less data required than a conventional survey grid. The advantages show up in processing time and model quality. Fewer images with better angular diversity mean faster processing. Lower altitudes enable safer flights in constrained areas.

Real application: communication tower inspections. A 50-meter tower in an urban area with surrounding buildings creates multiple problems. Standard approaches require high altitude for clearance, sacrificing GSD. Or they require multiple manual passes at different altitudes and standoffs, burning flight time and creating registration headaches in post-processing.

Circlegrammetry solves both. Define three circular orbits at different altitudes (base, mid-height, top section). Set the camera tilt to 60 degrees inward. The drone captures complete angular coverage of the tower structure in one automated mission. Processing software reconstructs the geometry cleanly because it has proper viewing diversity.

We’ve seen this cut inspection time by 40-60% compared to manual flight methods, with better output quality.

Vertical Scanning for Facades and Large Structures

Vertical scan automation can save several hours to 4-5 days depending on the structure. Manual flights fail to provide constant surface distance and consistent pixel size, making the footage unsuitable for processing and quantitative analysis.

The method is straightforward: the aircraft flies parallel to the vertical surface at constant standoff distance, capturing overlapping images in a vertical grid pattern. The technical challenge is maintaining that constant distance when the structure isn’t perfectly flat.

High-resolution DEMs and LiDAR data imported into mission planning software enable accurate vertical mission planning. Traditional SRTM elevation data lacks sufficient resolution for structures like dams.

One operator using automated vertical scanning for dam inspections achieved 1-millimeter resolution in the final 3D model. Post-processing software automatically mapped and quantified all cracks and defects on the concrete structure. Compare that to traditional rope-access inspection, where engineers manually measure each crack with calipers and record locations on paper drawings.

Moreover, drone vertical inspections are repeatable! When the flight plan is created once, it can be flown again to capture the same exact data from the same locations. This allows tracking how the structure changes over time, monitoring any cracks or defects, and planning repairs.

Solar Panel Inspections: Flight Geometry Matters

Solar thermal inspections require two sensors: thermal for fault detection, and RGB for reference. The flight geometry determines whether you collect usable data.

Flight direction must parallel the panel rows while maintaining a heading perpendicular to flight direction. Most basic flight planning tools don’t struggle with this configuration.

In most workflows, the camera tilt must match the panel angle (commonly 70 degrees) to keep the sensor perpendicular to the panel surface, preventing distortion and ensuring defects appear accurately.

Large solar farms present another challenge: coverage area. A 50-hectare facility requires careful mission segmentation, battery swap planning, and consistent imaging parameters across multiple flights. Desktop mission planning becomes necessary because you can’t effectively plan 200+ waypoint missions on a tablet screen in the field.

The MeteoSwiss research team made this point explicitly in their published paper. They needed to execute identical photogrammetry parameters across five different experimental sites with varying terrain. The team utilised UgCS for desktop planning, leveraging its DEM integration, mission templates, and 3D visualisation lets them maintain the precision their methodology requires. Tablet-based planning wouldn’t have supported that level of repeatability.

Custom camera profiles enable operations with any payload, including non-DJI thermal sensors. This matters for solar work because the best thermal sensors for panel inspection often aren’t DJI-manufactured.

The Trident Industries Approach: Corridor Mapping at Scale

Trident Industries’ drone team faced a common infrastructure challenge: photographing hundreds of kilometers of transmission lines across terrain that rises and falls through forests and hills. Flying close enough to spot damaged hardware meant staying low, yet improper waypoint planning could send the aircraft into a tower or compromise image quality.

Their solution combined several technical approaches:

Terrain-following with DEM integration maintained a consistent altitude above ground across changing elevation. The corridor mapping tool generated structured parallel flight lines automatically from GIS data.

Placemark tools enabled pre-definition of launch zones, improving crew coordination. Offline planning capability allows working in remote areas with limited or no connectivity.

The results: 70% reduction in planning time per mission, 30-40% faster field execution, zero redundant flights due to improved path accuracy, and consistent repeatable workflows across teams and aircraft platforms.

Scientific Validation: When Millimeter Accuracy Matters

The MeteoSwiss hail photogrammetry study provides valuable insights for commercial operators, as it tested fundamental photogrammetry principles under controlled conditions.

The challenge: measure hailstones across 220 square meters of uneven meadow before they melted. Required accuracy: 1 millimetre. Time available: under 20 minutes.

The team conducted systematic experiments with synthetic objects of known size (EPS spheres, glass pebbles, ice cones ranging from 10mm to 78mm). They placed 50 objects, flew photogrammetry missions at 8m AGL with 0.5m resolution DEM terrain-following, processed orthophotos at 1mm/px, ran machine learning detection, and compared detected sizes to actual measurements.

Results across five different grass surfaces:

- 98% detection rate

- Average error below 1mm (mean bias: -0.75 ± 1.6mm)

- Smallest errors for opaque objects

- Higher errors (2-3mm) for translucent objects due to reduced contrast

For context, automatic hail sensors use 5mm size classes due to roughly 20% measurement uncertainty. The drone method achieved comparable or better accuracy while covering areas hundreds of times larger.

When they surveyed the actual hailstorm event in Locarno at 12m AGL (1.5mm/px resolution), they captured approximately 4,000 hailstones in a flight lasting 1 minute 49 seconds. Detection accuracy was 81% under real-world conditions with low light, irregular surfaces, and visual interference from clover flowers.

The study documented that prior hail photogrammetry research using DJI Pilot 2 was limited to 12m AGL minimum (producing 1.5mm/px resolution). The capability to fly at 8m AGL and maintain that altitude across uneven terrain through automated terrain-following made the 1mm/px resolution feasible.

This matters for commercial work because the same principles apply. Your altitude capability and terrain-following precision directly determine your detection threshold for defects, cracks, and anomalies.

Practical Implementation: What Actually Works

Pre-mission planning matters more than most operators budget for. Time spent in desktop planning saves multiples of that time in the field. Import your site DEM. Model your flight paths in 3D. Check elevation profiles. Identify potential obstacles. Calculate battery requirements with margin.

Test your camera profiles before the job. If you’re flying custom payloads, verify trigger timing, image overlap, and gimbal control on a simple test pattern before tackling the complex site. It is better to discover issues when testing the equipment than on the job.

Plan for offline operation. Remote sites often lack cellular coverage. Map caching and elevation data downloads enable mission execution without internet connectivity.

Build mission templates for repeated work. If you’re inspecting similar structures regularly (cell towers, solar farms, bridges), create reusable templates with verified parameters. This standardises your output quality and accelerates deployment.

Consider processing requirements during capture planning. More images aren’t always better. Circlegrammetry delivers superior 3D reconstruction with fewer total images because angular diversity matters more than image count. This reduces processing time and storage requirements.

The Search and Rescue Validation

Morris Hansen’s SAR team conducted a high-altitude mission in Colorado searching for a missing trail runner. Operating from 11,000+ feet elevation, they needed to capture ultra-high-resolution imagery across 250+ acres of steep mountain terrain. Battery consumption was severe (20% just reaching the search area, 20% returning), leaving minimal operational margin.

The team used terrain-following with high-resolution DEM data (1-meter LiDAR) to maintain consistent altitude above highly variable terrain. Simultaneous multi-drone coordination split the search zones between two Mavic 2 Pro aircraft, avoiding coverage gaps while maximising efficiency.

Results: complete aerial coverage of four zones (27, 63, 84, and 83 acres) in approximately 6 hours, with zero areas requiring re-flight. The offline planning capability was critical since connectivity was limited. Over 200GB of imagery was collected for post-mission analysis.

The operator’s assessment: “The ability to control flights across multiple pilots has proven efficient. We covered more terrain in the same amount of time, with far more confidence.”

When to Use Which Method

Circlegrammetry works best for:

- Building corner and edge documentation

- Assets with many structures requiring 3D reconstruction from multiple angles

- Tight urban environments where altitude restrictions apply

Vertical circle inspections are best for:

- Telecommunication towers

- Isolated vertical structures (chimneys, silos)

Vertical scanning excels at:

- Large flat facades (buildings, dams, bridge abutments)

- Linear structures with minimal depth variation

- Crack detection and quantitative measurements

- Situations requiring millimetre-level resolution

Modified grid flights suit:

- Solar panel arrays

- Angled roof inspections

- Mixed terrain where some orbital capture combines with area coverage

Standard nadir grids remain optimal for:

- Horizontal roof condition assessment

- Large-scale site documentation where 3D reconstruction isn’t critical

- Progress monitoring where consistency matters more than detail

The Real Cost of Poor Data

Failed missions cost more than the repeat flight. If you’re a service provider, you’ve lost credibility with the client. If you’re an internal operator, you’ve wasted budget allocation and possibly missed critical maintenance windows.

Processing time for unusable data still burns resources. I’ve seen teams spend days trying to force bad imagery into reconstruction software, hoping different processing parameters will fix fundamental capture problems. It doesn’t work. Your output is only as good as your input.

The safety implications matter too. Manual flying near complex structures increases risk. Automated missions with verified flight paths, obstacle avoidance, and predictable behaviour reduce pilot workload and accident probability.

Moving Forward

Hard-to-reach asset photogrammetry isn’t the same workflow as terrain mapping. The tools that work beautifully for documenting construction site progress will often fail on vertical structures. The physics demands different approaches.

The good news: these challenges have known solutions. Circlegrammetry for complex 3D geometry. Vertical scanning for facades and structures. Terrain-adaptive planning for consistent GSD. Custom camera profiles for specialised sensors. Desktop mission planning for complex operations.

The operators getting this right aren’t using magic. They’re applying proper flight geometry, maintaining rigorous mission planning discipline, and using software that supports the specific technical requirements of vertical and elevated asset capture.

Your results will reflect the quality of your methodology. Choose methods designed for the actual problem you’re solving.

Drone Services Enquiry

Thermography | Inspections | Solar | Photogrammetry

Discover how drone technology can enhance your operations with a free quotation from our experts. Get a Free Quote or Make an Enquiry Today!

related posts

Drone Media Imaging now offers certified IEC 62446-compliant solar string testing, delivering complete electrical diagnostics for commercial PV systems. This new service verifies string integrity, insulation, voltage, current, and performance using advanced I-V curve tracing and Fill Factor analysis. Ideal for commissioning, troubleshooting, and maintenance, our testing supports safety, compliance, and ROI assurance. Combined with thermal imaging, we offer a powerful dual-inspection approach. Book today to ensure your solar array is operating safely, efficiently, and within international performance standards.

Ensure your solar panels are spring-ready with these 5 essential steps: 1) Pre-inspection planning, 2) Drone setup and calibration, 3) Aerial thermal imaging scan, 4) Data analysis and interpretation, and 5) Post-inspection maintenance. Utilize thermal imaging drones for efficient, accurate, and safe solar panel inspections this spring.