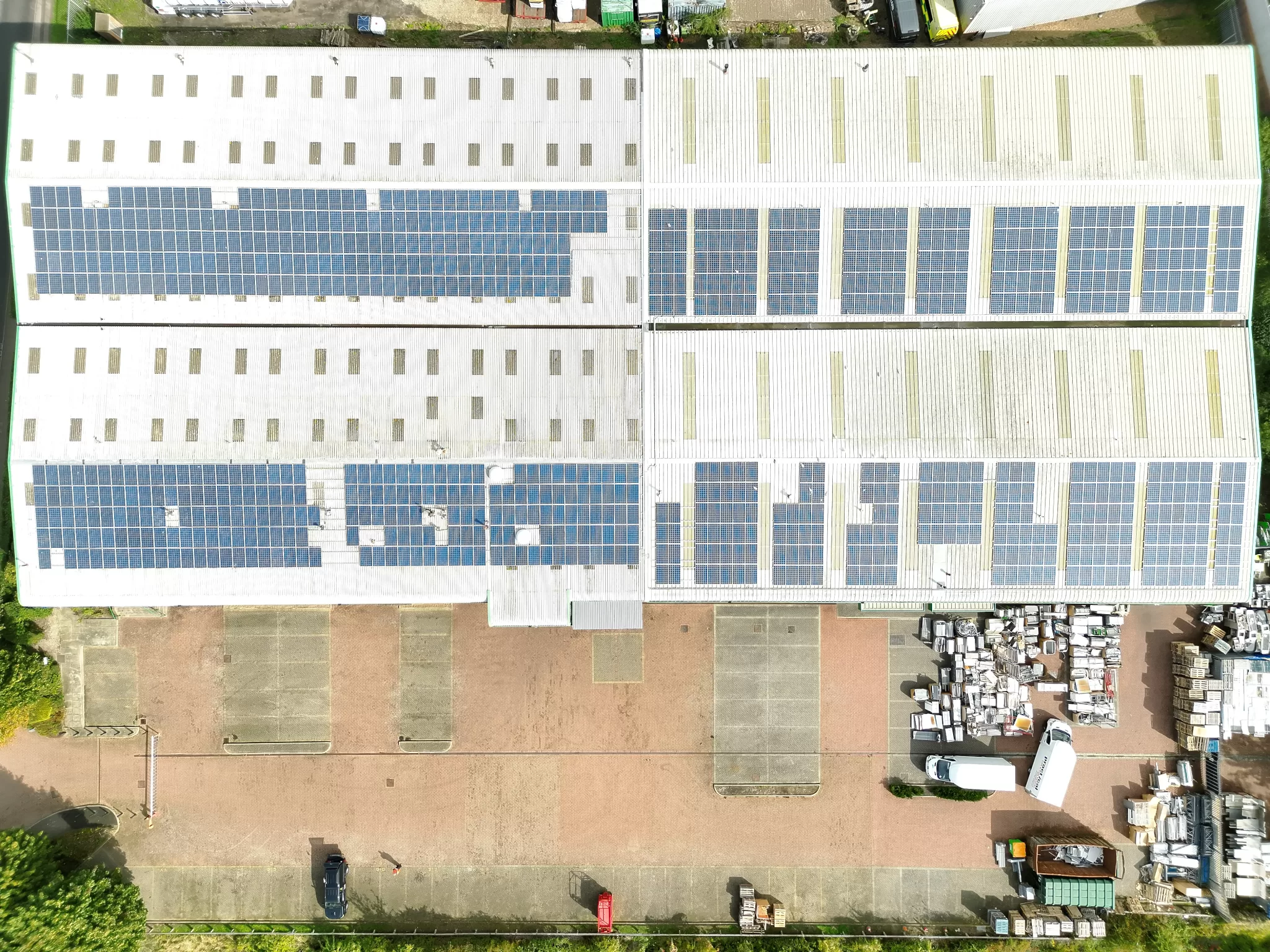

Drone Media Imaging carried out an IEC 62446-3:2017 qualitative solar thermography survey for MJL Electrical at the Wire Belt rooftop PV installation in Sittingbourne. The array was divided into four zones and inspected using a drone-mounted radiometric thermal camera under well-documented conditions: irradiance 731 W/m², ~30% cloud cover, SE winds at 6 mph, atmospheric temperature around 19°C and emissivity set at 0.90. Baseline modules were used in each zone to establish reliable comparative reference temperatures.

The survey identified string-level anomalies, most notably in Zone 1 (string 2) and across Zone 2, where large sections exhibited elevated temperatures relative to baseline. Numerous cell-level hotspots were documented, ranging from mild, uniform deltas through to more severe, non-uniform anomalies that could be symptomatic of cracking or localised failure. Additional observations included bypass diode behaviour (including bird-induced shading events), PID-like patterns on selected modules and soiling/debris-related heating.

No electrical testing was performed as part of this scope, so the report focuses on qualitative thermographic interpretation with clear recommendations for MJL Electrical to undertake targeted electrical checks where warranted. The outcome is a structured, standards-aligned view of array condition that supports informed maintenance planning and long-term PV asset management.

Project Overview

Subject

solar panel inspection, drone solar thermography, IEC 62446-3 survey, commercial PV inspection, solar hotspot detection,

Skills Used

Level 3 thermographic analysis, drone thermal imaging, IEC 62446-3 qualitative surveying, PV anomaly classification, environmental and parameter control

Portfolio Tags

solar inspection, thermography, commercial rooftop, IEC 62446-3, hotspot detection, drone survey, PV anomalies, renewable energy

IEC 62446-3 Solar Panel Inspection for Wire Belt, Sittingbourne

A Level 3 qualitative thermographic survey identifying cell, module and string-level anomalies across a commercial rooftop PV system..

aerial thermal inspection for solar PV systems

Client, Site and Survey Conditions

Drone Media Imaging was commissioned by MJL Electrical to complete an IEC 62446-3:2017 qualitative thermographic inspection of the rooftop solar PV system installed at Wire Belt’s facility in Sittingbourne, Kent. The objective was to assess the thermal behaviour of the array, identify developing faults and anomalies, and provide evidence-based guidance to support ongoing maintenance and performance management.

The survey was conducted on 20 September 2025 at 12:00, using a drone-mounted radiometric thermal camera (640 × 512, 30 Hz, ~19 mm lens) and an IEC-compliant solar irradiance meter. Environmental conditions at the time of inspection were:

Irradiance: 731 W/m²

Cloud cover: ~30%

Wind: SE at approx. 6 mph

Atmospheric temperature: ~19°C

Relative humidity: ~79%

Emissivity setting: 0.90

The array was divided into four zones to support systematic coverage and consistent comparison. Thermal baselines were established using clean, evenly irradiated modules within each zone, enabling anomalies to be evaluated relative to local module behaviour rather than in isolation.

The inspection followed the IEC 62446-3 “Simplified” qualitative method, focusing on relative temperature patterns, recurring behaviours and anomaly types rather than absolute temperature measurement.

IEC compliant solar panel survey

Cell, Module, Diode and String-Level Anomalies

Across Zones 1–4, the inspection recorded a range of anomaly types, all classified in line with IEC 62446-3 qualitative guidance.

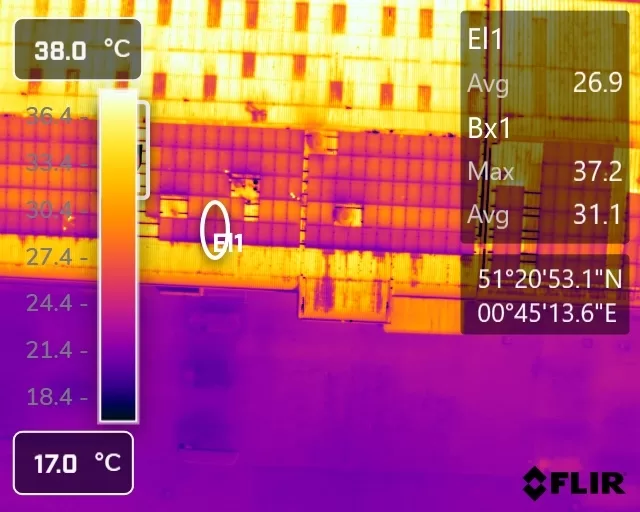

String-level anomalies

Evidence of string-level anomalies and/or faults in Zone 1 (particularly string 2).

In Zone 2, there was a raised surface temperature and thermal gradient across most of the zone, with one row/section closer to baseline.

These patterns are consistent with increased string resistance, imbalance, or broader string degradation, and typically warrant electrical verification such as IV curve tracing or insulation resistance testing.

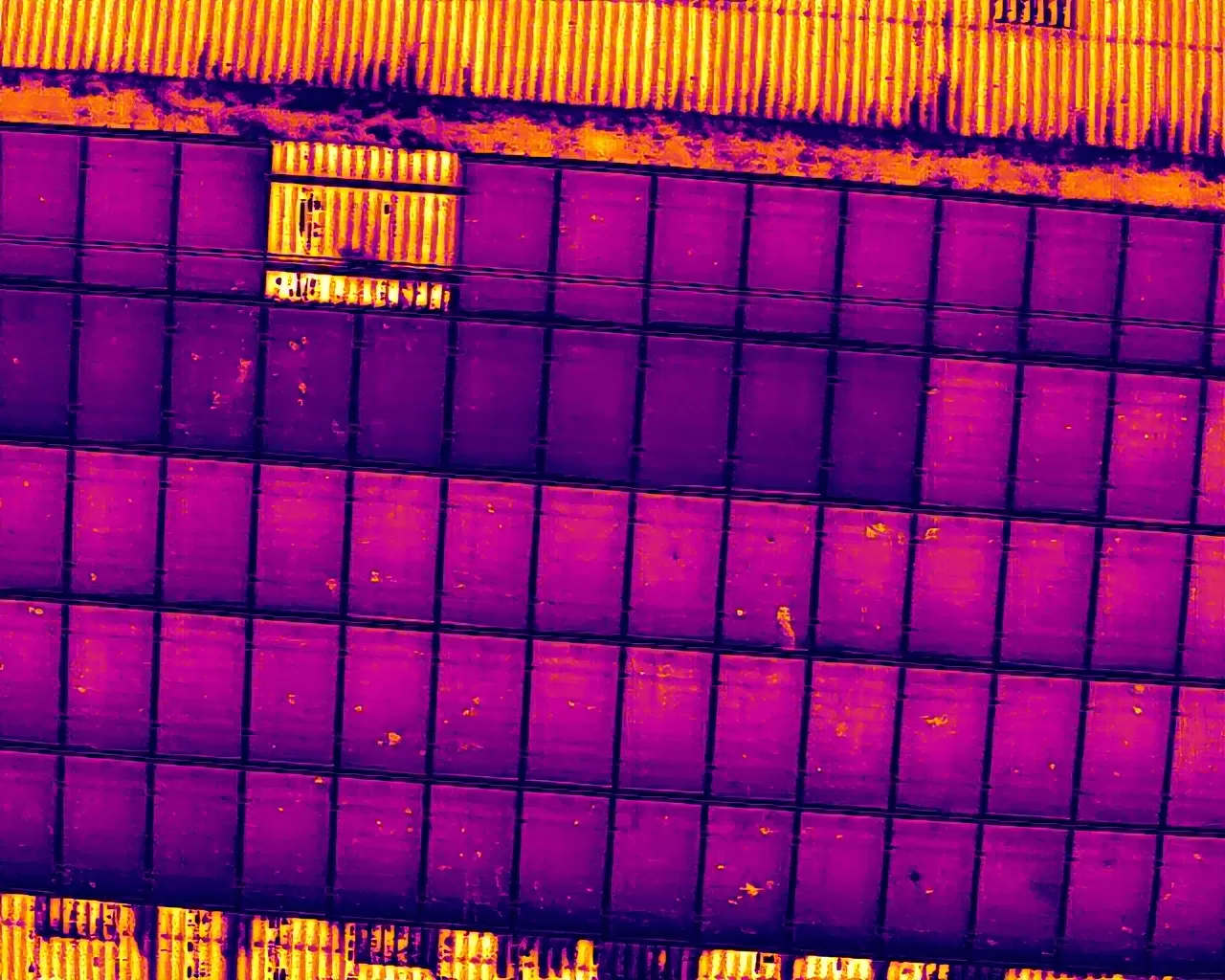

Cell-level faults / anomalies

Numerous localised cell-level thermal anomalies were identified.

Some presented as uniform, square-shaped hotspots ~4–6°C above baseline, suggesting early-stage degradation, increased series resistance or minor solder fatigue.

Others showed non-uniform, higher-delta hotspots (>10–20°C above baseline), which may indicate cell cracking, mechanical damage, or localised short-circuit conditions.

Very high-delta anomalies (approaching 35–50°C above baseline) were flagged as potentially severe internal failure modes requiring priority follow-up to avoid accelerated module ageing or safety implications.

Diode-related behaviour

Bypass diode anomalies were observed, including an example in Module B-5 (suspected diode malfunction or abnormal activation).

A separate case in Zone 3 (E-17) showed diode activation due to a pigeon sitting on the module, producing a classic “one-third hot” pattern.

These behaviours manifested as warmer module segments in clean thirds, aligning with standard PV diode architecture where diodes protect substrings of 20–24 cells in 60-cell modules.

Potential PID and module-level effects

Certain modules exhibited temperature patterns consistent with Potential Induced Degradation (PID), including edge-weighted heating and uniform elevation across the module surface.

Some strings showed multiple warmer modules, potentially indicating systematic degradation across a group of modules rather than isolated single faults.

Soiling and debris

The inspection also documented soiling and debris, notably bird-related contamination across sections of the array.

These areas produced localised heating, highlighting the impact of dirt build-up and wildlife activity on both performance and thermographic behaviour.

commercial rooftop solar fault detection

Interpretation, Electrical Follow-Up and Maintenance Planning

This inspection was delivered as a qualitative IEC 62446-3 thermographic survey only. No string-level or inverter-side electrical testing (IEC 62446-1) was included within the scope of this particular project. Instead, the thermal findings act as a diagnostic map, guiding MJL Electrical and the site operator on where to focus more detailed electrical investigations.

Recommended follow-up actions drawn from the survey include:

Electrical verification of key strings showing systemic heating (e.g., targeted IV curve tracing and insulation resistance tests).

Further investigation of high-delta cell hotspots to determine whether mechanical damage, cracked cells or severe resistive faults are present.

Review of modules with PID-like behaviour, particularly where patterns are repeated within the same string or batch.

A regular cleaning and inspection schedule to address soiling and bird debris, reducing shading-induced diode activation and avoidable performance losses.

The final report supplied to MJL Electrical included:

Zone-by-zone breakdown of anomalies

Anomaly classification (cell, module, string, soiling, diode, suspected PID)

GPS-referenced coordinates for each key observation

Thermal baselines and parameter settings

Explanatory narrative designed to support discussions with the site owner and (if applicable) the module manufacturer

For Wire Belt, this inspection provides a clear, evidence-backed view of their rooftop PV condition, enabling targeted maintenance rather than reactive fault-finding.