Solar String-Level Testing

IEC 62446-1 Certified Electrical Verification

Precision string-level electrical testing for commercial solar PV systems – verify performance, uncover hidden faults, and ensure safe operation.

Drone Media Imaging provides IEC 62446-1 compliant solar string-level electrical testing for commercial PV systems across the UK. Using calibrated test instruments and structured diagnostic workflows, we validate string performance, uncover hidden electrical faults, and deliver the evidence-based data required for warranty support, compliance checks, commissioning, and ongoing maintenance.

We test for:

Drone Media Imaging is now proud to offer certified solar PV string testing services in full compliance with IEC 62446-1 and IEC 61829 standards. This new service offering significantly enhances our inspection capabilities, providing clients with a complete diagnostic approach that combines aerial thermal imaging with detailed string-level electrical analysis.

Our string testing process delivers precision insights into the electrical health of your PV installation. By capturing key performance data across each string, we help you identify issues that are not always visible from thermographic surveys alone – such as insulation breakdowns, polarity errors, diode faults, PID effects, and module mismatch losses.

With the increasing complexity and scale of commercial solar installations, system owners and operators face rising demands for evidence-based performance validation, especially during post-installation handovers, warranty claims, insurance audits, or annual asset reporting. Our testing protocols are designed to meet these demands by offering transparent, standards-based documentation that supports technical due diligence, O&M planning, and regulatory compliance.

The testing is non-invasive and performed at string level with minimal disruption to ongoing operations. Whether your system is roof-mounted, ground-based, or integrated into an industrial or commercial estate, we deliver a flexible and scalable testing solution tailored to your installation’s architecture.

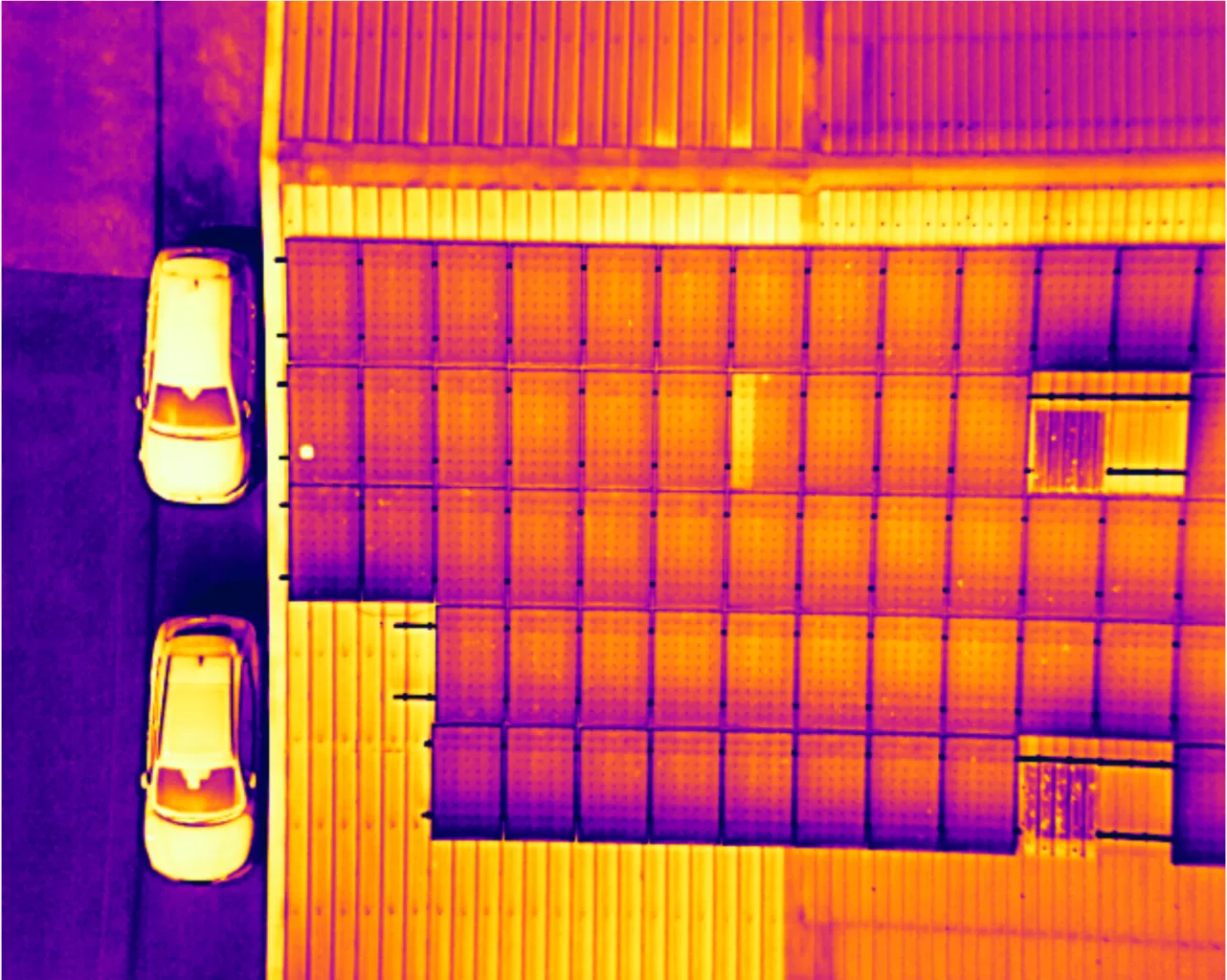

For clients already commissioning our IEC 62446-3 aerial thermographic inspections, this electrical string testing provides an ideal companion service — enhancing anomaly detection, improving diagnostic accuracy, and offering a robust foundation for confident decision-making around repairs, upgrades, and investment planning.

What’s Included

What is IEC 62446-1

IEC 62446-1 is the international standard that defines the testing, documentation, and inspection requirements for photovoltaic (PV) systems. It outlines a structured framework for electrical verification at the time of commissioning, during routine maintenance, and for system troubleshooting.

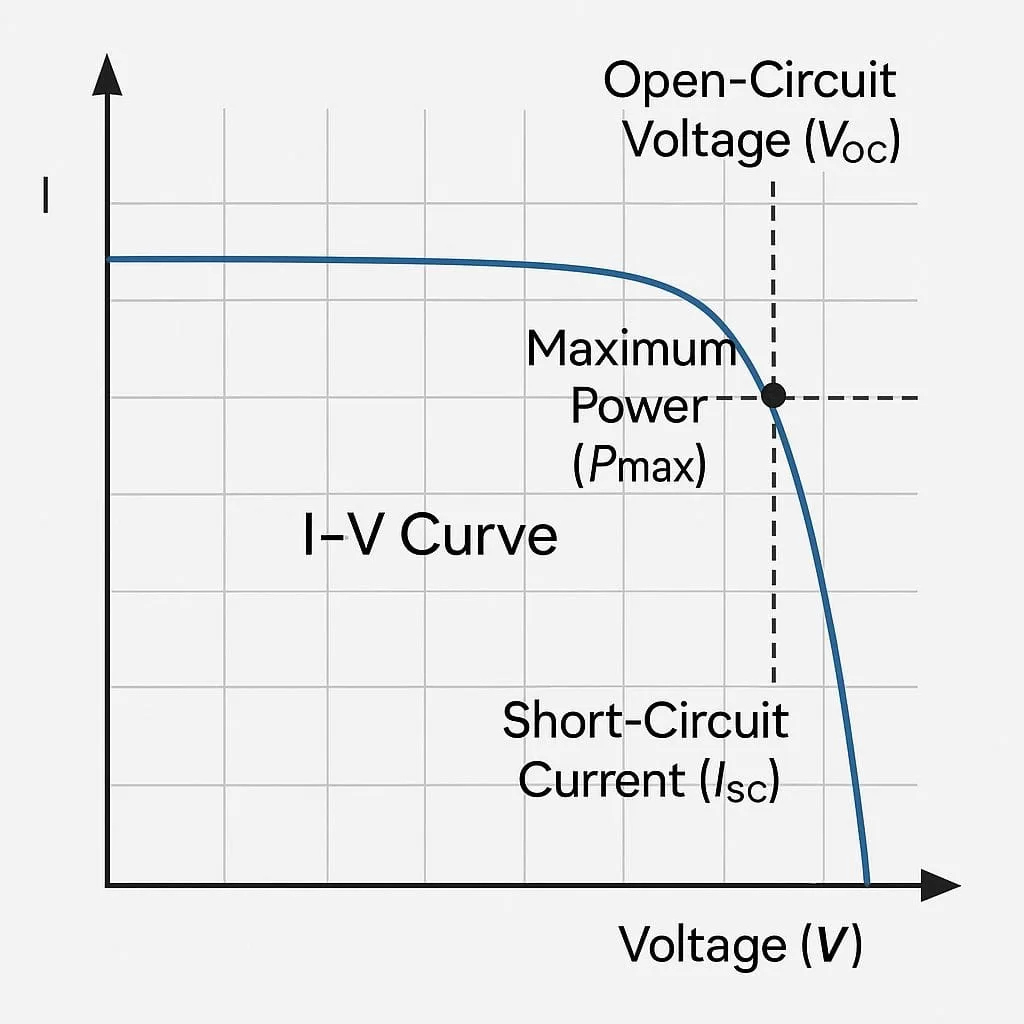

The standard ensures that PV installations are electrically safe, properly installed, and performing within design parameters. It covers essential tests such as continuity of protective conductors, insulation resistance, polarity, open-circuit voltage (Voc), and short-circuit current (Isc), and it mandates how these results should be recorded and reported. Compliance with IEC 62446-1 provides evidence-based assurance for owners, insurers, and financiers that the system meets recognised safety and quality benchmarks.

Under IEC 62446-1, Category 1 (Cat 1) tests are the minimum required for basic safety and system verification, typically including continuity of protective conductors, insulation resistance, polarity checks, Voc, and Isc measurements. Category 2 (Cat 2) tests extend this by incorporating I-V curve tracing and performance benchmarking, offering deeper diagnostic insight into string-level output and system efficiency.

This service is ideal for:

New system commissioning – validate workmanship, detect early faults

Routine preventative maintenance – identify degradation trends early

Reactive troubleshooting – isolate and confirm performance anomalies

Asset sale or refinancing – verify system condition before transaction

Warranty disputes or insurance assessments – provide independent validation

Why Does String Electrical Testing Matter?

Solar string electrical testing is a vital step in ensuring the ongoing safety, reliability, and efficiency of a photovoltaic (PV) system. While thermal imaging can reveal surface-level anomalies like hotspots or cell failures, string testing investigates the underlying electrical integrity of the system — from conductor insulation to correct wiring polarity and current delivery. Tests such as insulation resistance, polarity verification, open-circuit voltage (Voc), and short-circuit current (Isc) are designed to uncover faults that may not be visible but can severely impact safety and long-term performance. These include issues like deteriorated cabling, installation errors, faulty connectors, and hidden mismatch conditions — all of which can cause underperformance or pose fire and arc flash risks if left unchecked.

What sets string testing apart is its ability to quantify the real-world electrical output of each string under test conditions. Using tools like I-V curve tracing and maximum power point (Pmp) analysis, we can determine how closely each string performs relative to its theoretical maximum — accounting for variables such as irradiance, module age, and shading. Anomalies in the I-V curve shape or a reduced Fill Factor (FF) can indicate diode failure, soiling, potential-induced degradation (PID), or even early-stage module breakdown. By establishing this electrical profile at string level, we provide a granular, data-driven insight into how each part of the array is contributing to system performance, allowing owners and maintenance teams to make more informed decisions.

All findings are compiled into a clear, standards-compliant report suitable for maintenance records, warranty verification, asset transfer, or insurance purposes. The report documents the test methodology, environmental conditions, string-by-string test data, and diagnostic commentary where faults or anomalies are found. Where enhanced testing is selected, the report includes I-V curve plots for visual diagnosis and, if applicable, thermal imagery overlays showing correlated hot spots or degraded zones. This documentation not only satisfies the requirements of IEC 62446-1 and IEC 61829, but also supports clients in demonstrating due diligence, validating system performance, and planning proactive maintenance before faults lead to losses.

What We Test – Standard & Enhanced

All testing is conducted using certified, industry-grade instruments, following IEC 62446-1 and IEC 61829 protocols. The results help identify hidden performance issues, electrical safety concerns, or installation errors, and are suitable for both new commissioning and routine inspection programmes.

Standard Electrical Tests (IEC 62446-1)

Enhanced Diagnostic Tests (IEC 61829)

Voc – Open Circuit Voltage

Measures the maximum voltage output from a disconnected string under open-circuit conditions. Indicates string integrity and highlights mismatched modules, bypassed diodes, or shading-induced voltage loss.

Isc – Short Circuit Current

Captures the maximum current a string can produce when directly shorted at its terminals. Identifies underperforming strings, partial shading effects, or module degradation affecting current delivery.

Continuity of Protective Conductors

This test verifies that all protective earth (PE) conductors are correctly bonded and continuous from array to earth. Ensures safe earthing to protect against electric shock and fault current hazards.

Insulation Resistance Testing

Measures the resistance between conductors and earth to identify potential insulation degradation or damage. Helps detect moisture ingress, pinched cables, UV damage, or aged insulation before it leads to dangerous faults.

Polarity Check

Confirms that all DC connections are wired correctly, with positive and negative polarities correctly aligned. Prevents inverter damage, diode stress, and reverse-current faults caused by incorrect string connections.

I-V Curve Tracing

Plots the current vs voltage behaviour of each string under load, generating a performance ‘signature’. Highlights mismatch losses, cell degradation, diode faults, and PID through characteristic curve anomalies.

Pmax / Pmp / Fill Factor (FF)

Calculates the string’s true maximum power point and efficiency by analysing its I-V curve. A lower-than-expected Fill Factor indicates internal resistance, ageing effects, or connection defects.

Thermal Correlation (when paired with IEC62446-3 thermal inspection)

Matches electrical anomalies to thermal signatures for greater diagnostic clarity. Confirms whether thermal hotspots are caused by electrical defects, shading, bypass diode failure, or PID.

What Our String-Level Testing Provides

Our solar PV string testing service evaluates the electrical integrity of each DC string, identifying issues such as polarity errors, insulation breakdowns, degraded connectors, underperforming strings, and mismatched modules. These faults often remain invisible during visual or thermal inspections yet significantly impact system safety, performance, and long-term reliability.

By measuring key electrical parameters — including Voc, Isc, Riso, power (Pmp), and Fill Factor — we establish a clear performance profile for every string. This allows asset owners, O&M teams, and commissioning engineers to confirm correct installation, detect degradation patterns, and prioritise remedial action where needed.

Our approach provides transparent, standards-compliant documentation for technical due diligence, post-installation validation, routine inspections, asset transfer, and troubleshooting. Every test follows IEC-defined procedures, ensuring defensible results suitable for insurers, warranty providers, and engineering stakeholders.

How We Deliver It – Technical Methodology

All testing is carried out in accordance with IEC 62446-1 for electrical commissioning and maintenance testing, and IEC 61829 for I-V curve tracing. Using calibrated PV test instruments, we capture string-level electrical data under controlled environmental and irradiance conditions to ensure accuracy and repeatability.

Our process includes continuity verification of protective conductors, insulation resistance measurements, polarity checks, open-circuit voltage (Voc), short-circuit current (Isc), and enhanced diagnostics such as I-V curve tracing, Pmp, Pmax, and Fill Factor analysis. These tests collectively reveal electrical imbalances, shading-induced impacts, degraded cable insulation, diode faults, and performance deviations from manufacturer specifications.

Where paired with our IEC 62446-3 aerial thermal inspections, we correlate electrical anomalies with thermal signatures to distinguish between electrical defects, shading patterns, module degradation, soiling, and connection issues. This combined approach significantly strengthens diagnostic accuracy and reduces the likelihood of unnecessary module replacements.

Book IEC 62446-1 String-Level Testing

Get certified electrical verification and accurate performance analysis for your solar PV system. Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.

Investigating Cause

Thermal imaging identifies surface-level anomalies, but string-level electrical tests reveal the root cause of performance deviations. Hidden issues such as degraded connectors, cable insulation failures, polarity errors, PID, diode faults, shading inconsistencies and module mismatch can persist undetected unless measured electrically.

String testing verifies not only whether a string works, but how well it works, confirming its real-world ability to deliver voltage, current, and power efficiently. A reduced Fill Factor, distorted I-V curve shape, or imbalanced Voc/Isc readings are early warning signs of internal degradation or installation defects that impact long-term performance.

By identifying these issues early, owners avoid unnecessary module replacements, reduce downtime, prevent long-term efficiency loss, and improve operational safety by detecting faults that may otherwise pose arc-flash or fire hazards.