The Port of Tilbury grain terminal explosion created an extraordinarily complex industrial fire scenario requiring long-term monitoring and specialist interpretation. Drone Media Imaging provided calibrated radiometric thermal surveys over a 13-month period, capturing temperature trends, identifying hotspot behaviour and supporting decisions made by emergency planners and gold-command stakeholders.

Operating within strict exclusion zones, we used high-accuracy aerial thermography to measure temperatures exceeding 800°C and track the effectiveness of liquid nitrogen cooling. Our consistent dataset provided trusted intelligence throughout the response, contributing to safer operations and a controlled demolition strategy.

Project Overview

Subject

commercial drone thermography, industrial fire monitoring, emergency thermal surveying, grain silo heat mapping, long-duration thermal monitoring

Skills Used

Level 3 Thermography, Radiometric Drone Imaging, Emergency Response Operations, Temperature Trend Analysis, Industrial Inspection Protocols

Portfolio Tags

thermal imaging, industrial inspection, fire monitoring, grain terminal, emergency response, radiometric drone data, long-term monitoring, commercial thermography

Thermal Fire Monitoring Following the Grain Terminal Explosion at Tilbury Docks

High-accuracy aerial thermography used to track heat, detect rise-and-fall trends, and support emergency teams during a year-long industrial fire event.

Ongoing Fire Thermal Imaging

Critical Thermal Monitoring After the Port of Tilbury Grain Terminal Explosion

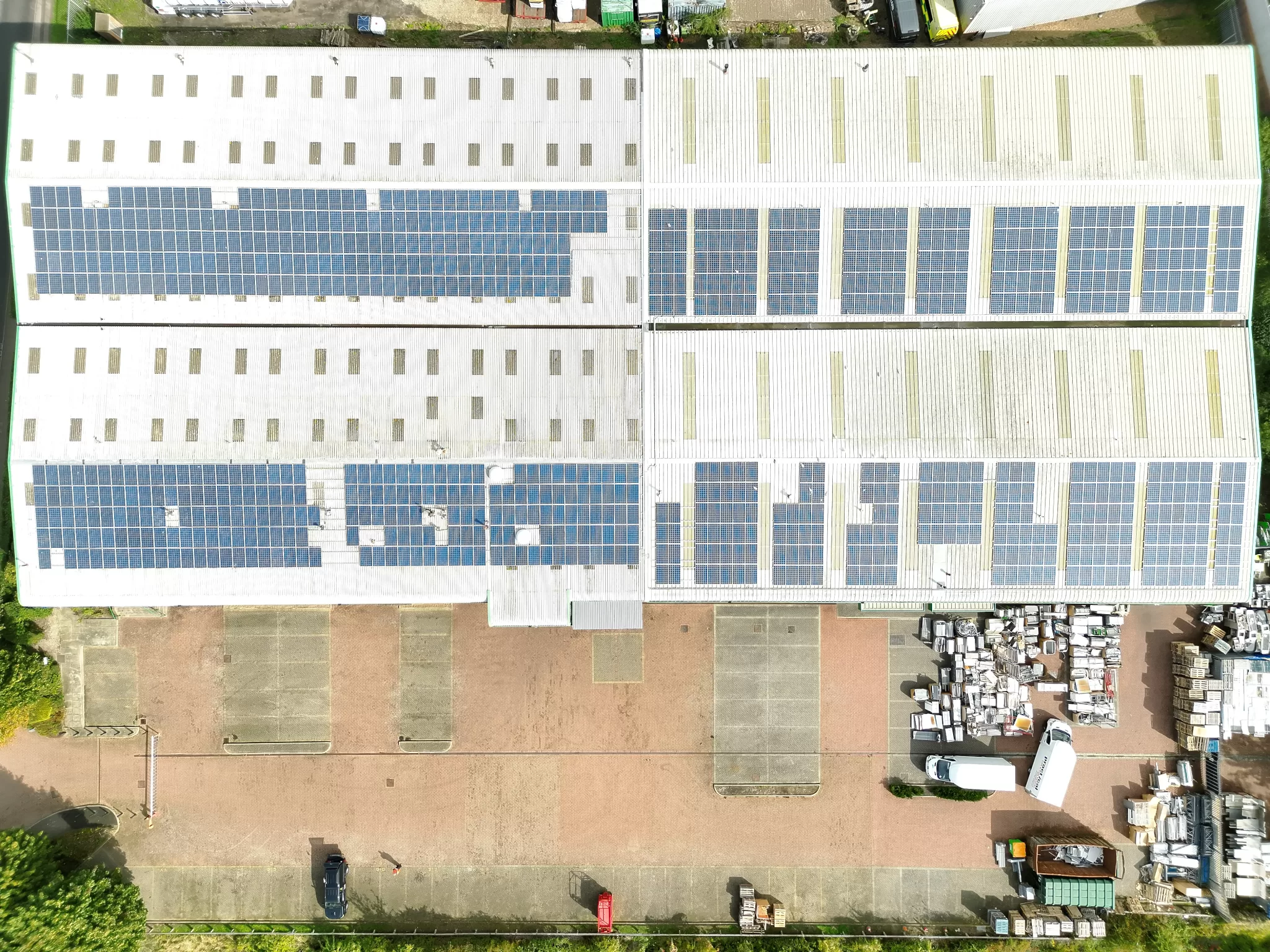

On 5 July 2020, a catastrophic dust explosion occurred at the Grain Terminal in Tilbury Docks, sending debris across the site and igniting a fire deep within the silo complex. With grain and dust fires capable of smouldering for months, conventional firefighting methods were unsuitable—introducing water risked structural failure and further explosions. As a result, emergency services established a long-term containment strategy, requiring continuous, reliable temperature intelligence to monitor the evolving fire behaviour.

Drone Media Imaging was contracted to deliver high-frequency radiometric thermal monitoring, providing temperature data that emergency planners could trust. Using drone thermography, we tracked heat pockets, identified rising temperature zones, and monitored cooling trends after critical interventions. These datasets helped determine whether the fire was intensifying, stabilising, or reducing—and supported strategic decisions around demolition, nitrogen injection and on-site safety management.

Operating within a 50-metre exclusion zone, we conducted multiple flights per day during the early phase, supplying calibrated thermal datasets to gold-command decision teams. Our work ensured that the multi-agency response had dependable real-time thermal insight during the most dangerous period of the incident.

Ongoing Thermography Survey

Long-Duration Thermal Surveillance Over a 13-Month Emergency Response

The incident developed into one of the longest-running industrial fires of its kind. Even with liquid nitrogen injection—deployed as the safest method of cooling and disruption prevention—internal temperatures remained volatile. Several silos recorded temperatures exceeding 800°C shortly after the explosion, and despite months of cooling, individual pockets continued to burn at several hundred degrees well into 2021.

Drone Media Imaging maintained an extended thermographic monitoring schedule, providing daily, weekly and monthly radiometric datasets over a 13-month period. Through consistent flight geometry, repeatable parameters, and stable emissivity control, we delivered reliable trend data that allowed responders to compare exact locations across time.

Drone access was only permitted after extensive risk assessment due to the instability of the structure and the potential for secondary explosions. Using professional-grade thermal equipment, we captured accurate temperature readings from standoff distances of around 20 metres above the silo roof—monitoring hotspots through structural breaches as small as fist-sized openings in reinforced concrete.

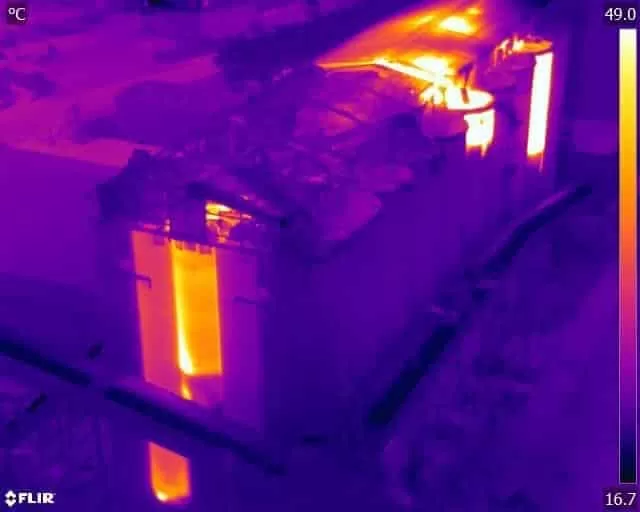

Our equipment enabled us to detect temperatures to 1/10th of a degree Celsius from 20m above the grain store roof. In the picture on the far left the temperature inside a silo, 7 months on from the initial explosion, was still showing around 380°C, seen here from flying 20m above the 30m tall silos and capturing data through a hole in the concrete the size of a fist.

The next picture demonstrates that the temperature in one silo was recorded at 511°C, 8 months after the initial grain store explosion. This is despite 8 months of liquid nitrogen being pumped in, proving just how difficult it is to manage fires of this nature.

Liquid Nitrogen in Fire Management

It was decided very early on that the post explosion and fire management would be a matter of containment and observation as grain can continue to burn for many weeks and months. Part of the strategy was to filter liquid nitrogen (LN2) into the base of the silos to bring down the heat and burn cycles, which proved to be a very effective control measure. Although the temperatures continued to remain high, the liquid nitrogen provided a sufficient cooling strategy and facilitated a successful temperature containment operation.

This image is a panoramic of the inside of the top floor above the 30 silos